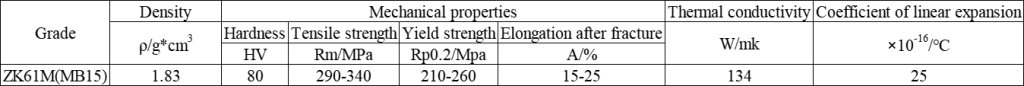

ZK series alloys mainly refer to Mg-Zn-Zr series magnesium alloys, currently one of the most widely used wrought magnesium alloys, of which the representative is ZK61 magnesium alloy. When its tensile strength exceeds 300 MPa after high-temperature forming, cooling, and artificial aging treatment, it has good plasticity, corrosion resistance, and machinability, and also is applicable to manufacture large forgings with complex shapes.

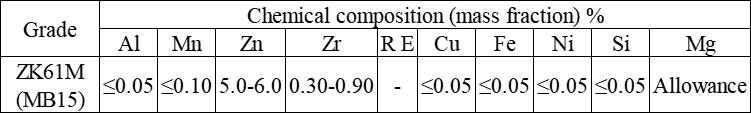

I.Chemical Composition of ZK61M

II.Physical Properties of ZK61M

III. Applications of ZK61M

ZK61M magnesium alloy is a typical zirconium-containing magnesium alloy. Old Grade MB15 magnesium alloy in China (No. 15 wrought magnesium alloy) is derived from the foreign Grade ZK60A with minor adjustments, which is quite similar to MB15. The zirconium element in the magnesium alloy has many advantages. Its main advantage is to refine the grain size, which boosts the mechanical properties such as tensile yield and elongation of the alloy, consequently making ZK61M magnesium alloy the magnesium alloy with the highest strength recognized in the current market. Besides, the zirconium element can reduce hot cracking, and has advantages such as corrosion resistance, high-temperature resistance, and creep resistance, further expanding the application scope of ZK61M magnesium alloy. Its zinc content ranges from 5% to 6%, which is close to the solid solubility of zinc in magnesium alloys. The increase in zinc content conducive to the solid solution strengthening. Meanwhile, when the zinc content is greater than 1%, the tendency of hot cracking will be increased.

ZK61M is one of the key materials for the energy-saving upgrade of automobiles by feat of its lightweight advantage (weight reduction of over 30%) and heat dissipation performance. For example, it is used in clutch housings and gearboxes of power system components, as well as in body and functional parts such as air conditioner casings and sensors. Moreover, racing suspension systems and transmission components also benefit from the high specific strength (tensile strength of 310–360 MPa) and impact resistance of ZK61M to improve dynamic performance.

Its excellent electromagnetic shielding performance (to prevent signal interference) and heat dissipation efficiency (thermal conductivity of approximately 100 W/(m·K)) enable the outer shells of electronic devices to be lightweight and have structural strength as well. Furthermore, its thermal conductivity is better than that of some aluminum alloys, which is applied in heat dissipation modules.

In industrial machinery, ZK61M is mainly applied in lightweight structural parts and corrosion-resistant components. With the help of its high stiffness (elastic modulus of 45 GPa) and shock absorption performance, the stability of equipment is optimized and the chemical stability against oils and alkalis, and it also can be applied to parts in chemical equipment that come into contact with mineral oil or alkaline media relying on its chemical stability.

Refer to the high-end sports equipment, ZK61M replaces aluminum alloy or carbon fiber to improve performance. In medical equipment, it is mainly used to strengthen portability through lightweight design. As for the new energy field, it primarily plays the crucial role in improving energy efficiency.

发表回复