MB25 is a high-strength deformation magnesium alloy of the Mg-Zn-Zr-Y series. It is usually supplied without heat treatment, either in the state of hot extrusion or hot forging. However, it can also be used in an artificially aged state. It is mainly used for processing extruded products and die forgings. The tensile strength at room temperature, yield strength, and high-temperature instantaneous strength of this alloy are all superior to those of the high-strength magnesium alloy MB15.

The plasticity, toughness, and corrosion resistance of the alloy are similar to those of the magnesium alloy MB15. The process plasticity of the alloy at room temperature is poor, while it has good process plasticity at high temperatures. Therefore, the pressure processing and forming of the parts need to be carried out under a heated state. The cutting processing performance of the alloy is good. Due to the poor welding performance of the alloy, it is not recommended to be used as a welding part. It can replace some medium-strength aluminum alloys for the stressed components.

1. Chemical composition and properties of MB25 alloy

In the air environment, the MB25 alloy is prone to oxidation, and the oxide film formed on the surface is not dense and cannot play a protective role. The stress corrosion tendency is small. The surface is treated by oxidation and coated for protection, and it can work reliably in the air environment.

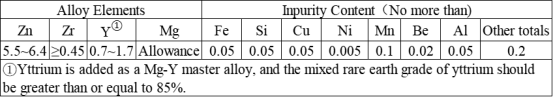

Chemical composition and impurity content (mass fraction) of MB25 alloy (%)

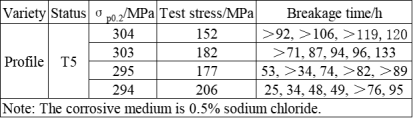

The stress corrosion resistance of MB25 alloy material

2.The stress corrosion resistance of MB25 alloy material

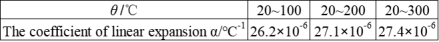

The linear expansion coefficient of MB25 alloy

3. Mechanical properties of MB25 alloy

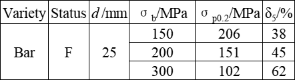

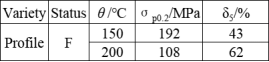

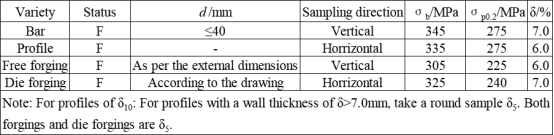

The room temperature hardness of MB25 alloy is not less than HBS65. The room temperature tensile properties are shown in the table below. The high-temperature instantaneous strength of extruded bars is shown in the table below. The high-temperature tensile strength of extruded profiles is shown in the table below. The mechanical property values specified by the technical standard are shown in the table below.

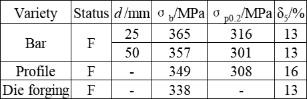

The room-temperature tensile properties of MB25 alloy material

The high-temperature instantaneous strength of MB25 alloy bars

The high-temperature tensile strength of the MB25 alloy extruded profiles

The allowable mechanical property values of the MB25 alloy material

4. Process performance of MB25 alloy

(1) Forming performance. The forming performance of the MB25 process is similar to that of the MB15 alloy. It has good plasticity within the temperature range of 280 to 400℃. The rough forging blanks are easy to be trimmed. When manufacturing forgings and die forgings using extruded billets, the forging temperature is 320 to 390℃. The heating temperature of the mold is 200 to 300℃. The lower limit forming temperature of the profile is 270 to 290℃, and the holding time is 1/4 to 1/2 hour.

(2) Welding performance. The welding performance of the MB25 alloy is poor, and it is not recommended to be used as a welding component.

(3) Heat treatment process. The parts of MB25 alloy generally do not undergo heat treatment. They are used in the state of hot extrusion or hot forging. However, artificial aging treatment can be adopted. The artificial aging schedule is: 170℃, holding for 10 hours, and air cooling.

(4) Surface treatment process. The surface oxidation treatment of the MB25 alloy is followed by painting protection. To improve the surface protection performance of magnesium alloys, a new method of oxidation treatment followed by sealing and painting can be adopted. For semi-finished products and parts that are regularly stored and transported, the surface should be protected from scratches and attention should be paid to oil-sealed packaging, and rain erosion should be prevented.

(5) Cutting and grinding performance. The MB25 alloy, like other magnesium alloys, has excellent processing performance.

5. Application of MB25 alloy

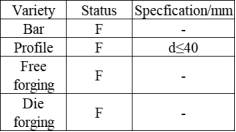

The MB25 alloy has passed technical appraisal and installation application, and has replaced some medium-strength aluminum alloys and high-strength magnesium alloy MB15 for the main load-bearing components. The operating temperature is generally not more than 150℃. The current varieties, specifications, and supply status are as follows in the table.

发表回复