MB22 is a heat-resistant wrought magnesium alloy of the Mg-Y-Zn-Zr series, mainly produced as sheets. Its room-temperature tensile strength is slightly higher than that of MB3 alloy, and its high-temperature yield strength, high-temperature instantaneous strength and compressive yield strength are significantly better than those of other magnesium alloys (such as MB3 and MB8). The alloy has good formability and weldability, and shows no tendency for stress corrosion. Through deformation, it can be produced into plates, bars, tubes, profiles and forgings of various sizes.

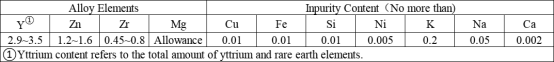

I. Chemical Composition of MB22

The chemical composition and impurity content (mass fraction) of MB22 alloy are shown in the following table.

II. Performance of MB22

Melting and Casting Process:

MB22 alloy is usually melted in a steel crucible resistance furnace or a gas reverberatory furnace. Fluxes are used for protection and refining during melting. Yttrium is added in the form of Mg-Y master alloy and zirconium in the form of Mg-Zr master alloy. To reduce the loss of yttrium, special fluxes can be used for protection and refining. Water-cooled semi-continuous casting is adopted. During casting, to prevent bottom cracking of the ingot, molten pure magnesium can be used as a base, and SO2 or a mixed gas containing SF6 can be used for protection to prevent oxidation and combustion.

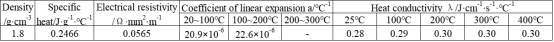

The physical properties of MB22 alloy can be found in the description of MB15 alloy

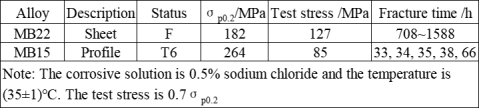

The chemical properties and corrosion resistance of MB22 alloy. The alloy has no stress corrosion tendency. The tensile stress corrosion performance is shown in the following table. It can be seen from the table that the stress corrosion resistance of MB22 alloy is better than that of MB15 alloy with low stress corrosion tendency. However, it is prone to corrosion when used for a long time in industrial and marine atmospheric environments. Therefore, chemical oxidation treatment and painting protection are required during use.

Tensile stress corrosion performance of MB22 alloy material

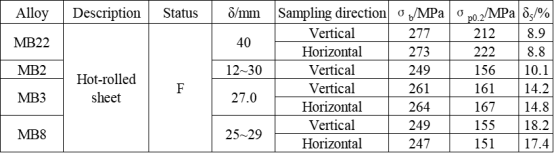

The tensile properties of MB22 alloy at room temperature are shown in the following table. By comparing the table, it can be seen that the tensile strength of MB22 alloy is higher than that of MB2 and MB8 alloys, and slightly higher than that of MB3 alloy. The yield strength is significantly better than that of MB2, MB3 and MB8 alloys.

The tensile properties of MB22 alloy at room temperature

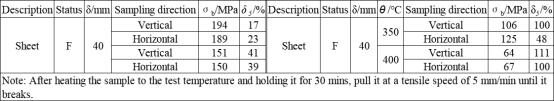

High-temperature tensile properties of MB22 alloy material

III. Application of MB22

Compared with cast magnesium alloys, wrought magnesium alloys have finer microstructure, more uniform composition and higher density. Therefore, they have advantages such as higher strength and elongation. Meanwhile, under the same working conditions, they are lighter than wrought aluminum alloys.

This alloy can be directly used in the state of hot extrusion or hot forging, and its performance can be further enhanced through artificial aging treatment. This makes MB22 suitable for components that require high-temperature resistance (such as above 200℃). Additionally, the hot plastic processing technology of MB22 alloy (such as hot deep drawing forming) has been explored, indicating that it is applicable to components that require complex shapes or precise forming.

发表回复