2025/02/05

Abstract

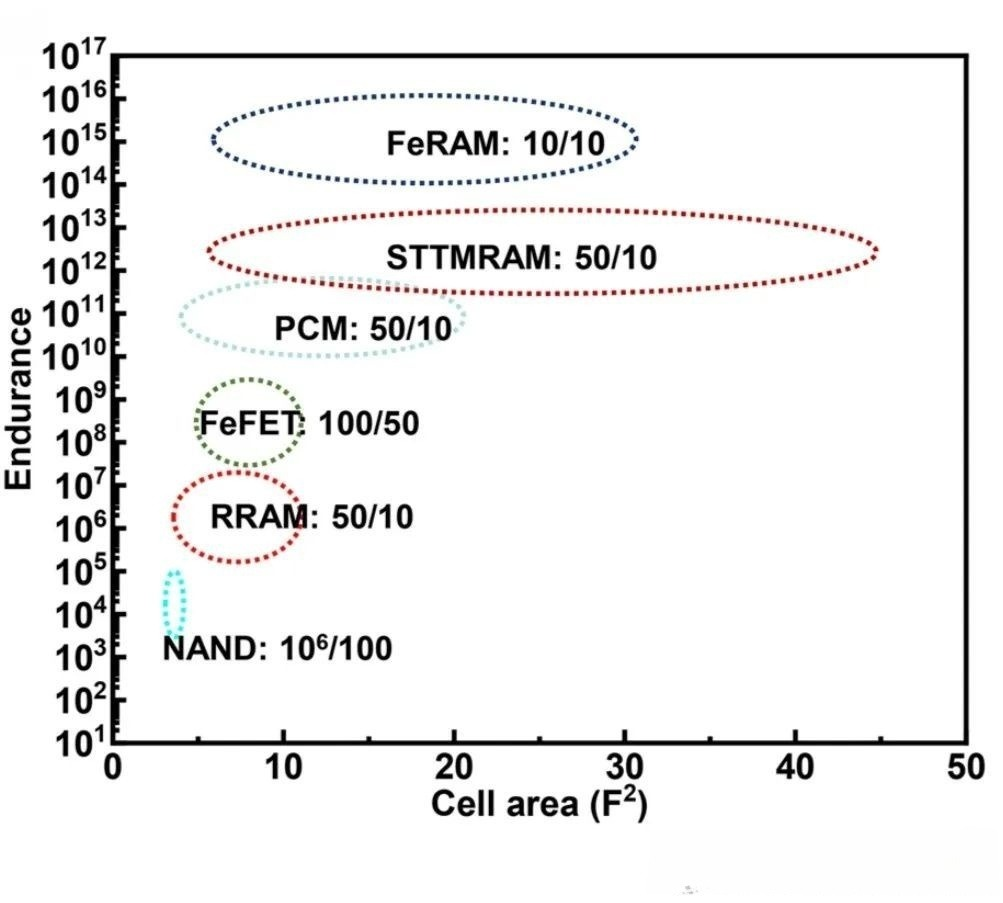

Ferroelectric random access memory (FeRAM) has faster read write speeds and better endurance than other random access memories (RAM). The read and write speeds and endurance of ferroelectric field effect transistors (FeFET) are also better than commercial NAND flash memory.

An ideal ferroelectric memory (FeM) requires the following characteristics: good CMOS compatibility, suitable remnant polarization (Pr) to achieve larger storage capacity, optimized coercive electric field (Ec) to enable long-term retention and a large memory window, as well as an excellent durability and low operating voltage, and a stable ferroelectric phase to ensure high uniformity between devices.

Ferroelectricity of AlScN

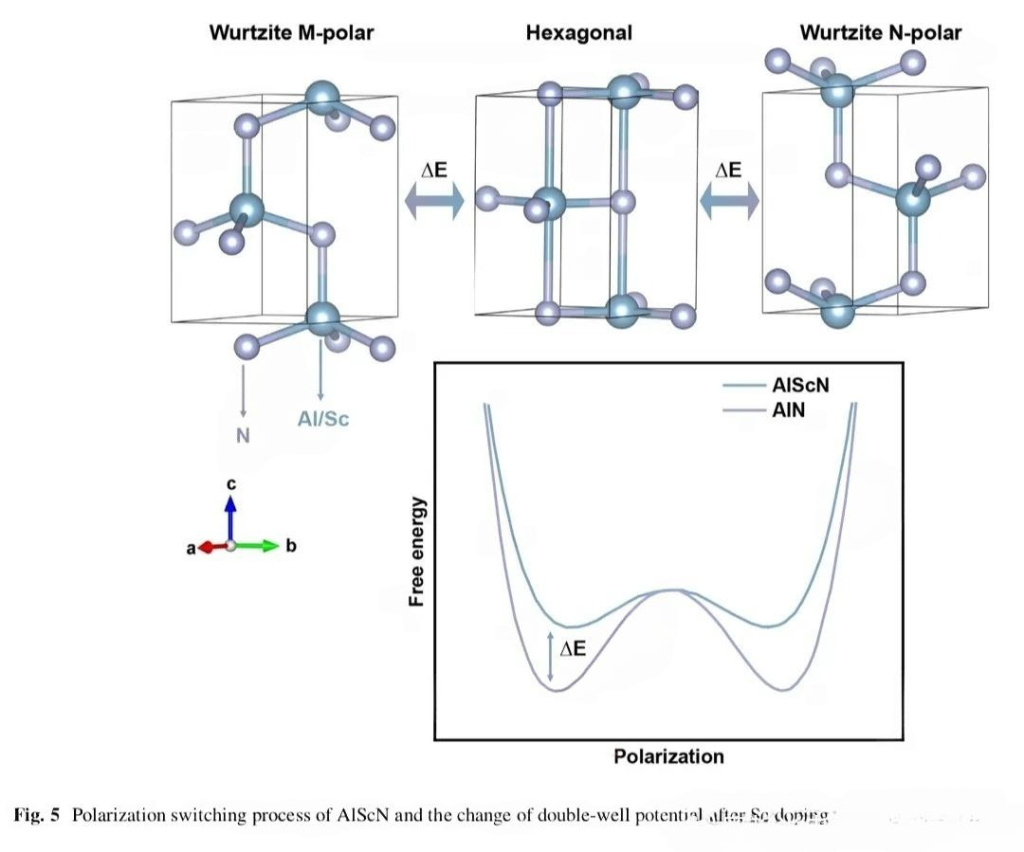

Pure AlN is a piezoelectric material rather than a ferroelectric material because it cannot reverse polarization before dielectric breakdown. Sc doping flattens the energy landscape of AlN and reduces the ferroelectric switching energy barrier. The metastable hexagonal ScN sheet is a transition state between the two polarization directions of the wurtzite structure, reducing the energy barrier between the two polarization states.

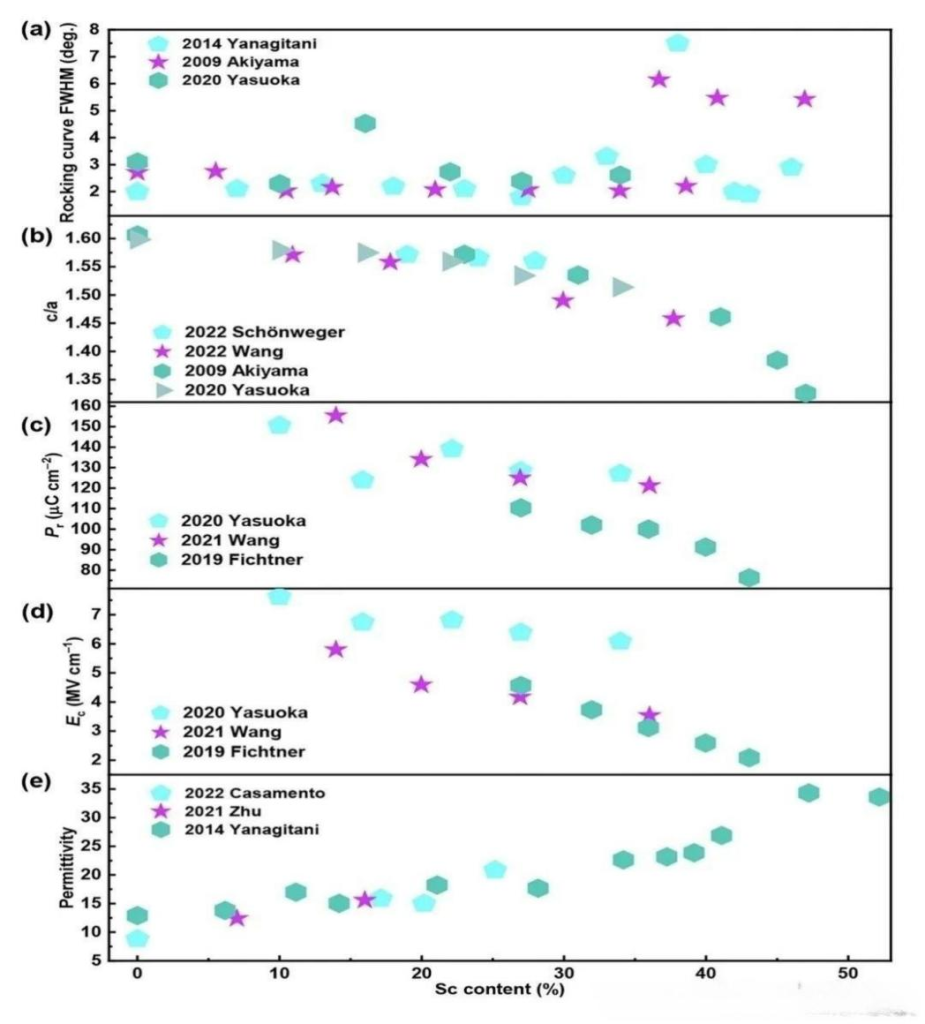

As the Sc content increases, c/a decreases, and both Ec and Pr decrease. Yet, when the Sc content exceeds 30at%, the FWHM increases significantly and the crystal quality decreases. As the Sc content increases, the dielectric constant increases. When the in-plane mechanical stress changes from -0.8 to 0.5GPa, Ec decreases from 5 to 4MV/cm. For better ferroelectric properties, it is necessary to optimize the in-plane stress with different Sc contents to reduce Ec and leakage current and maintain the breakdown field strength.

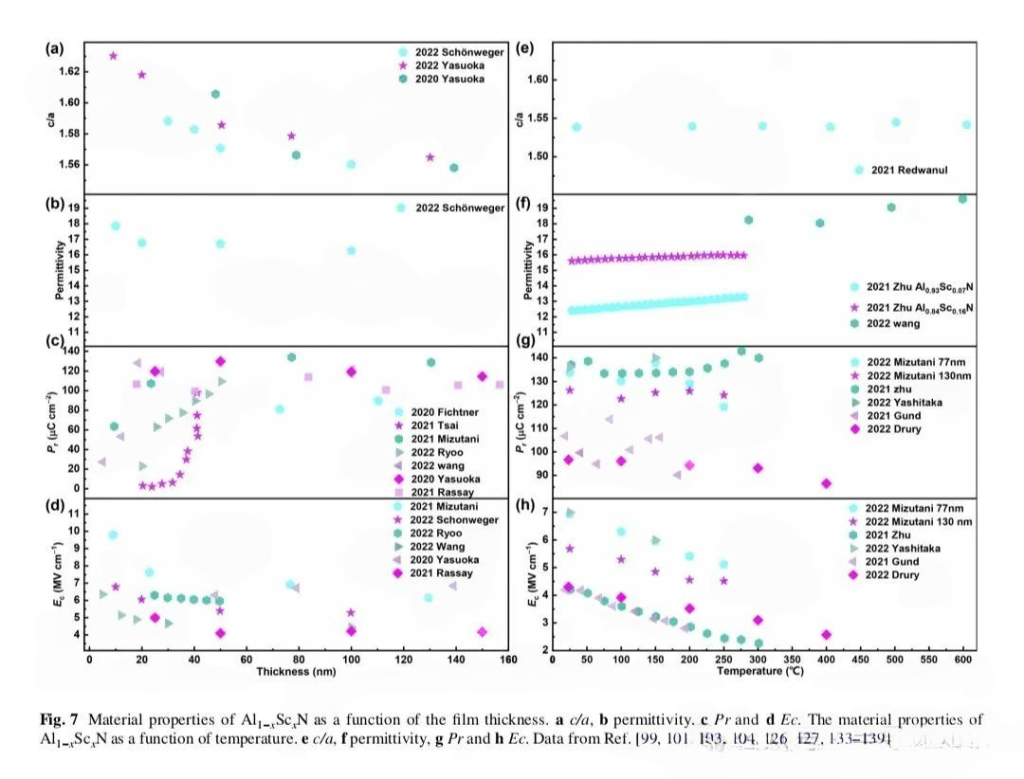

When the film thickness is less than 50nm, the c/a of AlScN decreases with the thickness increase and tends to be stable when it is greater than 50nm. As the film thickness decreases, Pr decreases, and Ec increases, especially when the thickness is less than 20nm, Ec ∝ d^(-2/3). The c/a, dielectric constant, t, and Pr of AlScN do not change with temperature, and Ec decreases with increasing temperature, but it is still higher than other ferroelectric materials.

The characteristic switching time limit of AlScN (5.98×10^-14s) is more than three orders of magnitude faster than that of HZO (1×10^-10s), while its activation field (96MV/cm) is one order of magnitude higher than that of HZO (8.94MV/cm), which is the reason why AlScN has a high Ec.

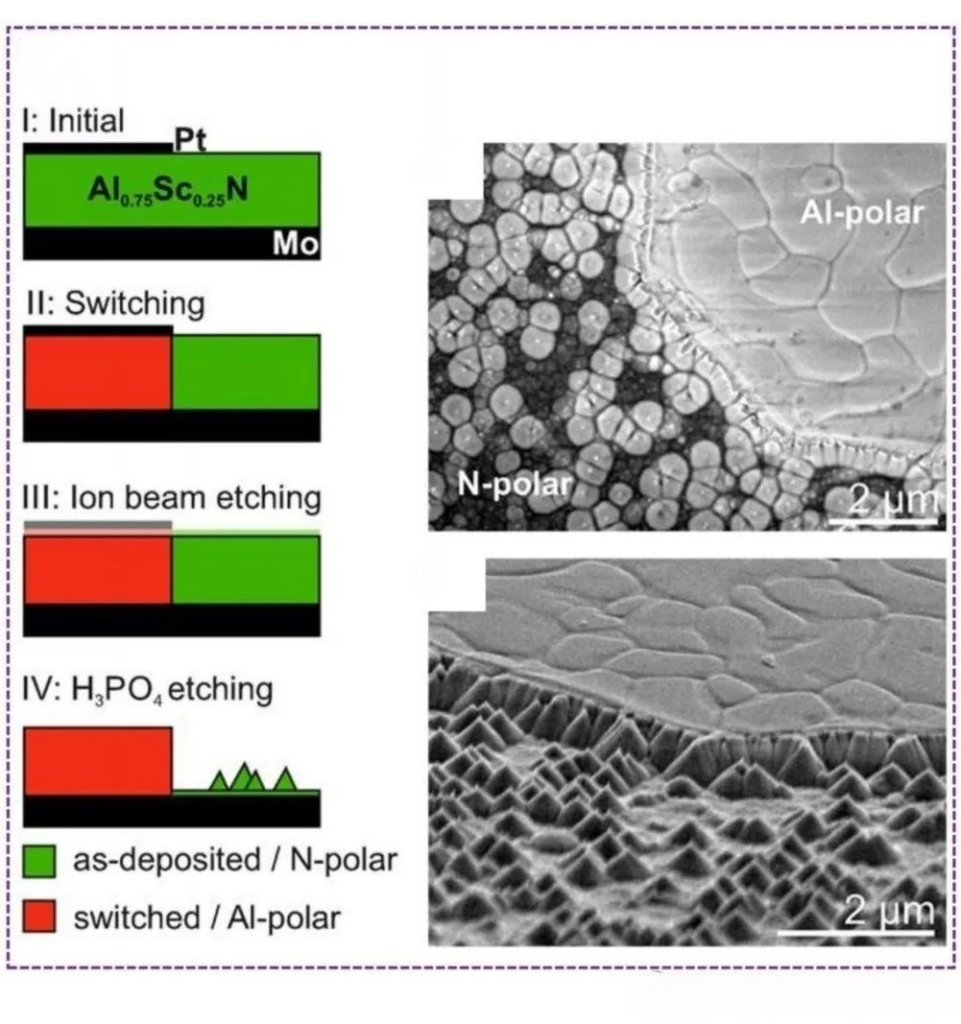

The N-polar AlScN surface is more easily etched by acid and alkali (H3PO4, KOH), and a conical morphology remains on the surface.

Ferroelectric Device Applications

Advantages of ferroelectric memory: low power consumption and high speed. Problems: high Pr and low dielectric constant are required, and the read operation of FeRAM is destructive. The charge stored in the capacitor is selectively turned on by the transistor and released to the sense amplifier to determine the storage state. To restore the information after each read, reprogramming is required; therefore, the capacitor should have sufficiently high endurance and moderate Ec. Due to the pulse width dependence of the switching voltage, the trade-off between operating speed and voltage requires an electric field twice the coercive field to operate. On the one hand, a large Ec gives the material a large memory window and excellent retention behavior. On the other hand, considering that the operating voltage is proportional to the coercive field Ec and the thickness of the ferroelectric layer, the Ec of thin AlScN films should be reduced to be compatible with CMOS logic. Only by optimizing the doping concentration and strain level to achieve a moderate Ec in the film, high Pr and low ε wurtzite structure ferroelectrics seem promising for FeRAM.

The tunneling barrier height of FTJ is determined by the polarization state, so the domain structure can control the tunneling conductance. In general, ferroelectric materials with high Pr can deplete the charge at the FTJ electrode interface, thereby increasing the width of the tunneling barrier and suppressing the off-state current, resulting in a large ON/OFF ratio. Considering the requirements of the ferroelectric layer in FTJ, AlScN with large Pr and high Ec has great potential in FTJ-based products.

The performance advantages of FeFET are reflected in the ON/OFF ratio, memory window (MW), retention, and endurance. If Pr is too high, the depolarization field will also increase, resulting in poor retention performance. The high Ec of AlScN makes Edep/Ec low enough to obtain good retention. Both the memory window and the operating voltage are proportional to Ec and the thickness of the ferroelectric layer. The large memory window promoted by high Ec is crucial for correctly distinguishing the storage state. However, high Ec leads to high driving power values and a typical endurance of <10^5 cycles. Based on the above analysis, to obtain better comprehensive performance, the Ec of AlScN film should be changed by changing the Sc concentration, strain engineering, and/or superlattice/multilayer structure. It is worth mentioning that the low dielectric constant of AlScN is beneficial to reducing the electric field in the interface layer and improving the durable cycling performance of FeFET with a metal-ferroelectric-insulator-semiconductor (MFIS) structure.

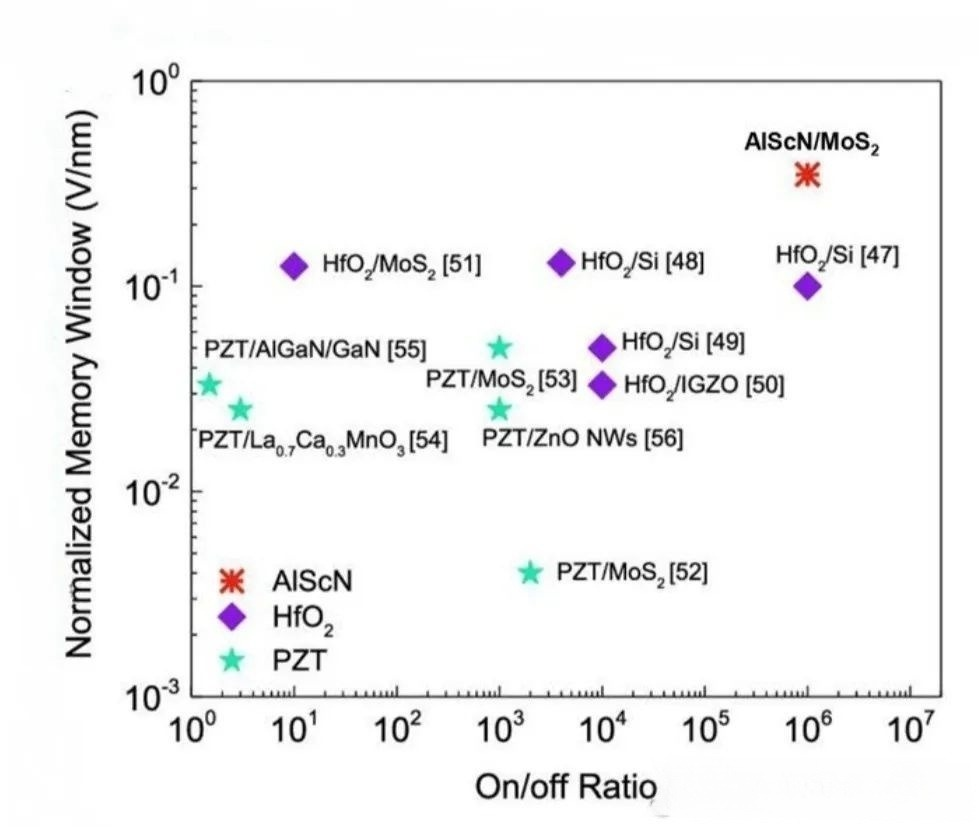

On/off ratio and memory window of FeFET

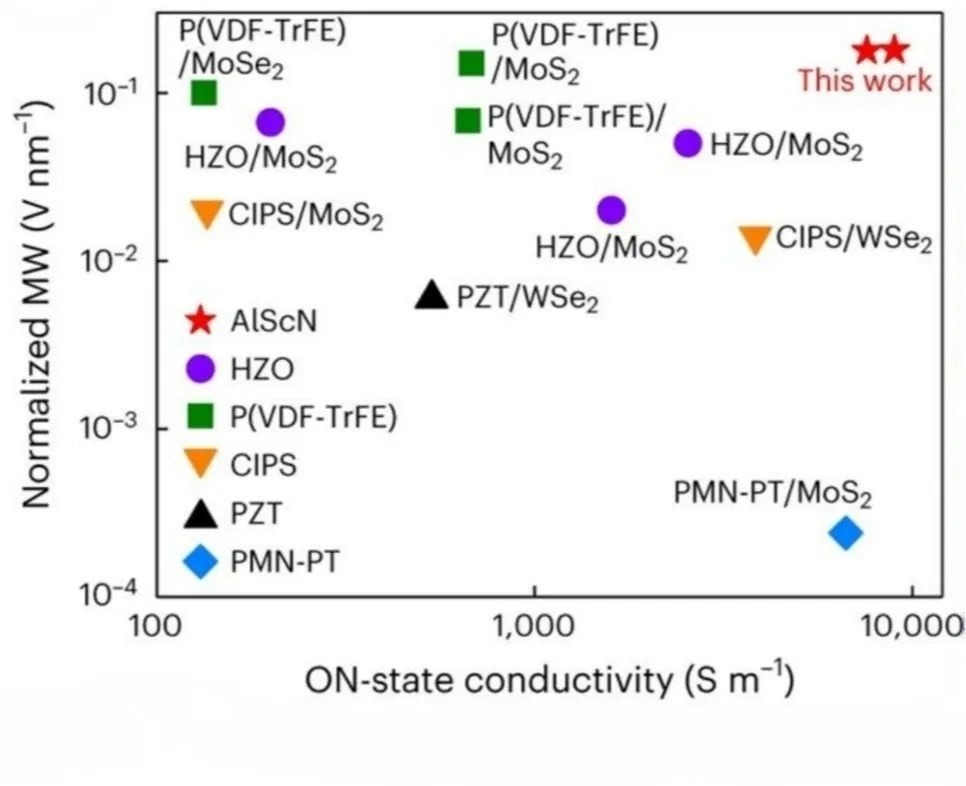

Comparison of normalized storage window and on-state conductivity of FeFETs with different ferroelectric materials and MoS2 as a channel

Defects may form during the manufacturing process of FeFET, leading to interface reactions or diffusion, which deteriorate the quality of the ferroelectric layer. Highly oriented fcc or bcc metals or TiN can provide hexagonal templates for [001] oriented wurtzite ferroelectrics.

The inevitable depolarization field in FETs, the low Ec of conventional ferroelectrics, and the unsatisfactory ON/OFF ratio hinder the commercial application of FeFETs. Ferroelectric AlScN has a large EC to screen the depolarization field, a large Pr to modulate the channel conductance, and a large ON/OFF ratio to meet the requirements of CMOS compatibility. At the same time, compared with other ferroelectric materials, AlScN has a lower dielectric constant, which increases the voltage load in the ferroelectric layer. The fatigue characteristics of AlScN-FeFET are already comparable to flash memory, and its the read and write speed is also faster than those of flash memory. Flash memory has extremely high integration density and reliability. From a potential commercial perspective, 3D integration of AlScN-FeM needs to be explored.

The storage window of FeFET is mainly determined by the coercive voltage (Vc) of the ferroelectric layer, which is proportional to the thickness and Ec of the ferroelectric layer. The incomplete shielding of the semiconductor channel in FeFET introduces a large depolarization field, resulting in poor data retention time. High Ec is beneficial for improving the retention characteristics of the device. However, an ultra-large Ec requires a higher operating voltage and limits the durability of FeRAM. Cycling at high voltage leads to performance degradation. Therefore, a moderate Ec is considered to be the best choice for achieving balanced performance in ferroelectric applications. The Ec of AlScN can be reduced by adjusting the concentration of introduced cations such as Ga, B, and Sc. Changing the substrate or using rapid annealing to increase the in-plane stress can also reduce Ec. In addition, to reduce the required voltage level, it is necessary to use ultra-thin films. In FeFET, large Pr leads to a significant depolarization field. When the applied electric field is close to Ec, AlScN will experience significant leakage current, resulting in poor cycling durability. This problem is usually attributed to nitrogen defects, dislocations, and inhomogeneous domains. A high vacuum deposition system is required to grow thin films in a high nitrogen content environment to suppress the formation of nitrogen vacancies. In addition, a suitable substrate can not only provide an epitaxial template to suppress dislocations and inhomogeneous domains but also induce appropriate strain to increase the polarization energy distribution.

发表回复