2025/05/21

The Mg-Mn(Ce) series belongs to high-strength deformation magnesium alloys. In China, industrial deformation Mg-Mn(Ce) alloys include MB1 and MB8. These alloys have good thermal deformation properties and are suitable for rolling, extrusion, and forging, and can be produced into plates, strips, tubes, bars, and forgings.

MB8 is a modified version of MB1 by adding a small amount of Ce (0.15% – 0.35%) alloy. Since Ce can refine grains and inhibit the formation of twins, it is conducive to the increase of yield strength (especially compressive yield strength), making it suitable for processing structural components that bear longitudinal bending loads. In addition, Ce also improves heat resistance. MB8 can operate at temperatures below 200°C, but the working temperature of MB1 cannot exceed 150°C. This indicates that the comprehensive performance of MB8 is higher than that of MB1. The process plasticity of MB8 is good (including stamping, extrusion, and rolling performance) and it has high corrosion resistance, has a low SCC tendency, is easy to weld, and is a widely used deformation magnesium alloy. Sheets can be used to manufacture the shells and heat dissipation components of electronic consumer goods, as well as precision structural parts, such as the vibration components of notebook computers and hard disk drives, and the shells of projectors. Die forgings can be used to manufacture complex-shaped components; and tubes are mostly used in systems requiring corrosion resistance such as gasoline and lubricating oil systems.

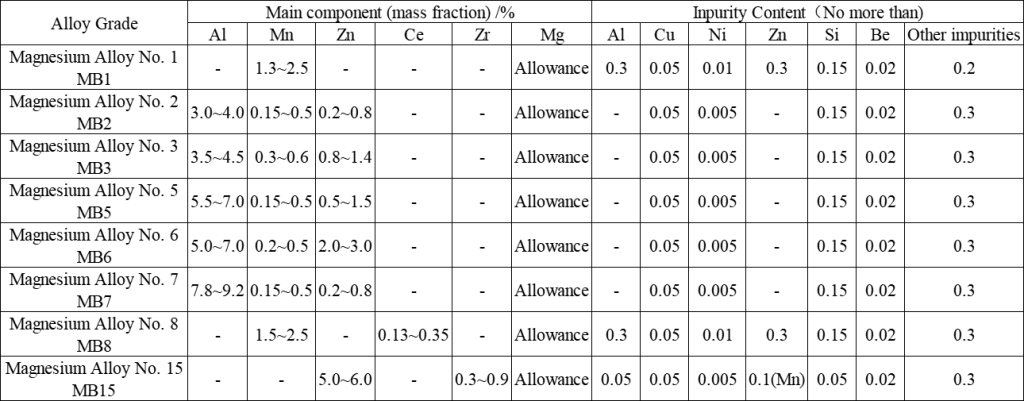

Ⅰ. Chemical composition of MB8 alloy

The grades and main components of China’s shape-morphing magnesium alloys

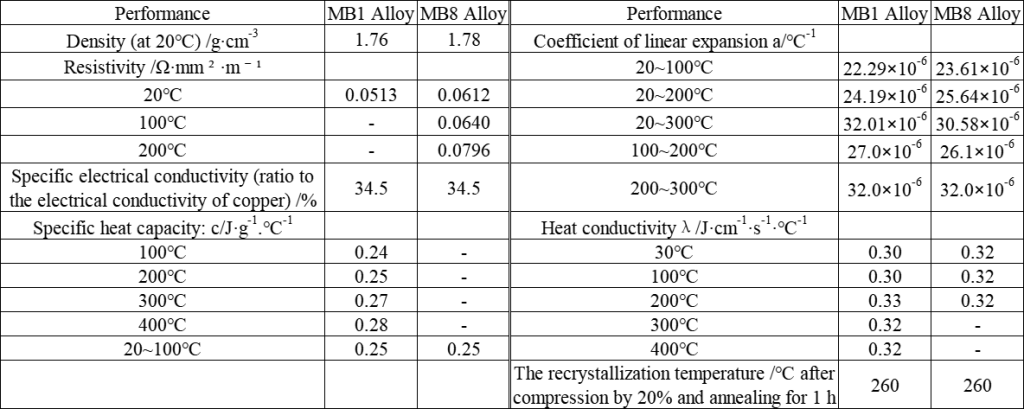

II. Physical Properties of MB8 Alloy

The physical properties of MB8 alloy

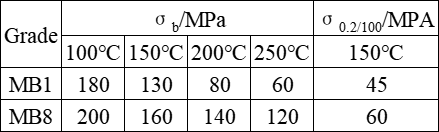

The high-temperature performance of MB8 alloy

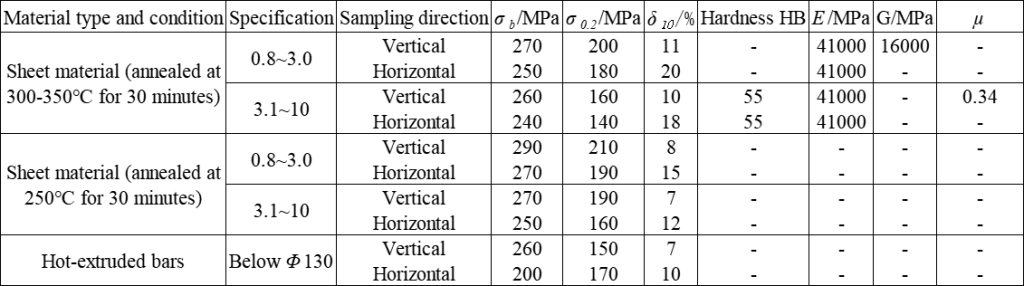

The room-temperature mechanical properties of MB8 alloy

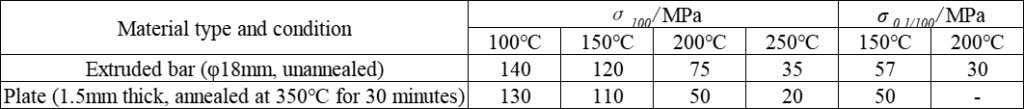

The endurance strength and creep degree of MB8 alloy

III. Application of MB8 Alloy

The MB8 magnesium alloy possesses outstanding mechanical properties, including high strength, high hardness, good toughness, and corrosion resistance. These properties make the MB8 magnesium alloy highly competitive in various engineering applications. The sheet of the MB8 alloy is used to manufacture the shells and heat dissipation components of electronic consumer products, as well as precision structural parts, while the forged parts can be used to manufacture complex-shaped components. The profiles and tubes are used to manufacture parts that require good corrosion resistance, such as those in gasoline and lubricant systems.

发表回复