The role of neodymium in magnesium alloys

1. Enhancement of Mechanical Properties

Solid Solution Strengthening: Following solid solution treatment, neodymium atoms dissolve into the magnesium lattice, inducing lattice distortion and increasing resistance to dislocation motion, thereby significantly improving the yield strength of the material.

Precipitation Hardening: During aging treatment, neodymium reacts with the magnesium matrix to form precipitates such as Mg₁₂Nd. These fine, uniformly distributed secondary-phase particles further enhance material strength and creep resistance by impeding dislocation movement.

2. Improvement of Corrosion Resistance

The addition of neodymium markedly enhances the gas tightness and corrosion resistance of magnesium alloys, which holds significant implications for their broad applications in aerospace, automotive engineering, and communication electronics.

3. Microstructural Refinement

Neodymium contributes to the precipitation of Nd-rich phases within magnesium alloys. These precipitates, typically distributed within grains and along grain boundaries, play a critical role in improving the alloy’s creep resistance.

4. Influence on Melting and Heat Treatment

During melting, neodymium reduces the alloy’s melting point, expands the liquid-phase region, and modifies microstructural evolution, phase transformations, and grain growth. These alterations profoundly impact the alloy’s mechanical properties and thermal stability.

In summary, neodymium not only strengthens the mechanical properties of magnesium alloys but also enhances corrosion resistance and refines microstructures, collectively advancing the development of magnesium alloy technology.

Ⅰ.Comparative Properties of Nd and Mg

| Element | Mg | Nd |

| Melting Point (°C) | 650 | 1024 |

| Boiling Point (°C) | 1107 | 3074 |

| Density (g·cm⁻³) | 1.738 | 7.004 |

| Crystal Structure | hcp | hcp |

| Atomic Radius (nm) | 0.162 | 0.181 |

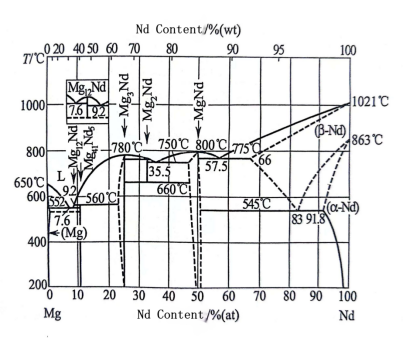

Figure 1 Mg-Nd Binary Phase Diagram

II. Preparation Technology of Mg-Nd Master Alloy

Mg-Nd intermediate alloy is mainly produced by metal direct reaction method, which is to directly prepare Mg-Nd intermediate alloy by adding metal neodymium in proportion to high temperature molten magnesium solution. The method offers operational simplicity, rapid dissolution kinetics, stable composition control, and precise alloying element incorporation.

Figure 2 Mg-Nd Master Alloy

III. Technical Specifications of Mg-Nd Master Alloy

Table 2 Composition of Mg-Nd Master Alloy

| Grade | Specification | Impurity Content | Remarks |

| MgNd20 | Nd:20±2% | Fe≤0.05%、Si≤0.02%、Mn≤0.02%、Al≤0.02%、Ca≤0.02%、Ni≤0.005%、Cu≤0.005% | Nd content customizable upon requests |

| MgNd25 | Nd:25±2% | ||

| MgNd30 | Nd:30±2% | ||

| MgNd35 | Nd:35±2% |

发表回复